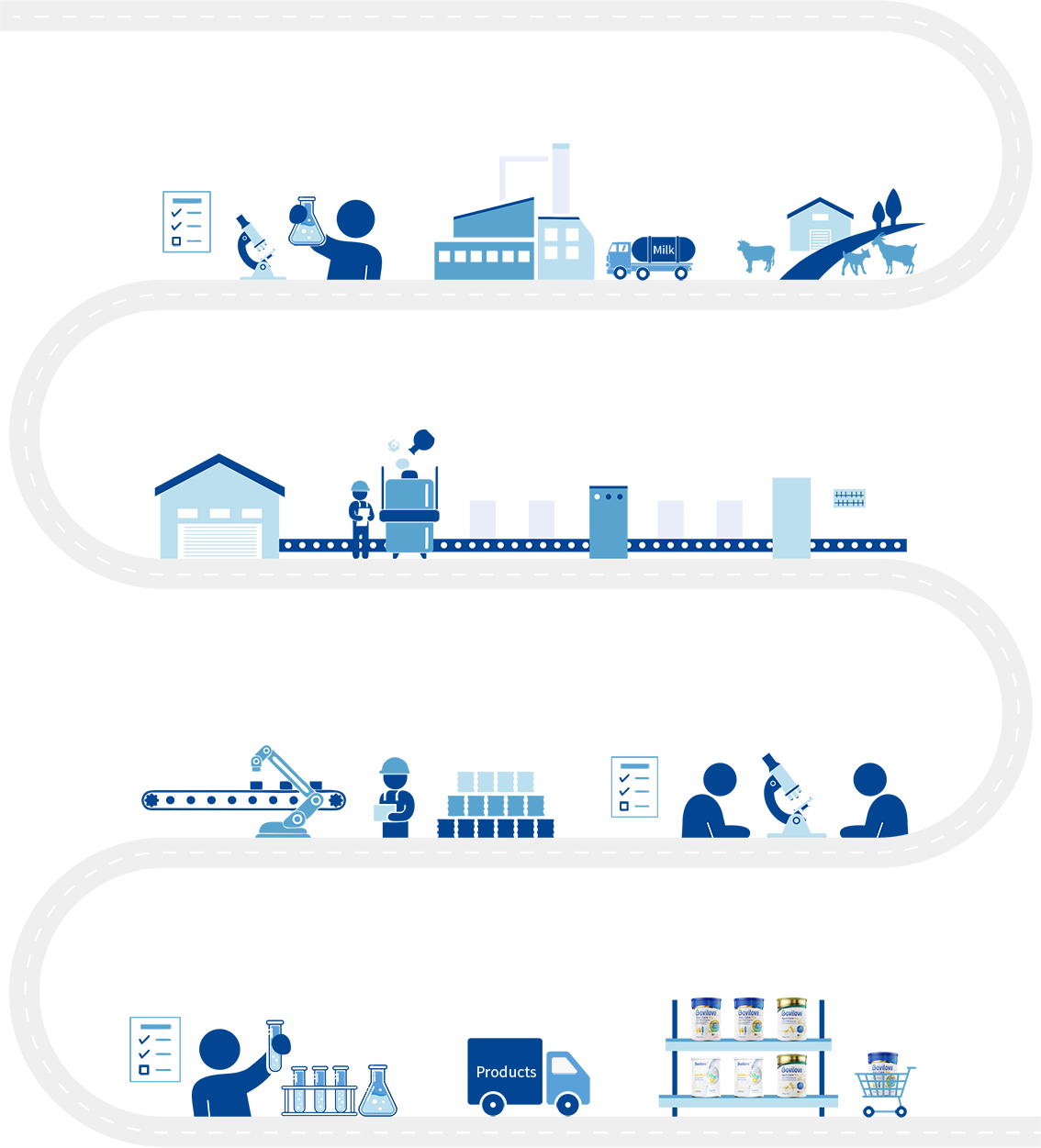

We are passionate about ensuring only the FINEST ingredients are sourced

100% Australian milk is used in our products. We add a wide range of top-quality nutritional ingredients which would include vitamins, minerals, and oils.

We are passionate about ensuring only the SAFEST manufacturing process and strict tracing and quality controls are adhered to

The dairy plant has been manufacturing dairy since 1911, this heritage and knowledge is critically important when manufacturing specific dairy based foods.

With a history of manufacturing quality dairy products, in a state of the art manufacturing plant that is ISO 9001 accredited, and apply HACCP based quality system for dairy food safety, you can rest assured that Bovilove is in safe hands.

We have a “One Cow / One Goat certificate” intelligence tracking process, to ensure we track and manage our raw milk supply.

We follow 30 point quality monitoring process, testing each ensuring our quality standards are met at each point.

We are passionate about delivering the

best wholesome NUTRITION that

nourishes every stage of life

The result in sourcing only the finest ingredients and following safe manufacturing, is the composition of a range of dairy based nutritional supplementary products that meets the required specifications and guidelines. Providing wholesome nutrition at each stage of life.

Our 100% Australian fresh milk arrives straight from the farm and is tested upon arrival at our Shoalhaven factory before being unloaded.

The treated raw milk and added ingredients is then turned into powder during spray-drying process.

Strict hygiene rules apply in the powder production environment : air is filtered (99,95% of the external particles are removed); rooms are over pressurized.

The production environment is sampled to ensure good hygiene is always met. Materials such as wood, paper and carton are banned from these high care areas ensuring no contamination.

Access the production environment is restricted to trained and dedicated operators. Personnel or special visitors can only enter following a strict process by changing their clothes, shoes, wearing hairnets, most importantly wash and disinfect their hands.

Each batch is sampled and tested before leaving the production site to confirm it is safe and in compliance with our specifications.

Once all quality checks are undertaken and approved our products are then dispatched.